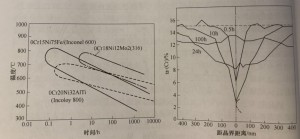

The commonly used Ni-Cr alloy is the more widely used Inconel 600. The sensitizing temperature range of this alloy is very wide. At 300-850°C, Cr23c6 is precipitated. The intermetallic corrosion of Inconel 600 with a carbon content of only 0.017% is related to the sensitization temperature and time with the chromium carbides of Cr7C3. It can be seen that the most sensitive temperature range is 700 – 850°C. Intergranular corrosion can be produced by sensitization in only a few minutes. Prolonging the sensitization time (about 104h) at a lower temperature (300 – 350°C) can also lead to intercrystalline Corrosion, this temperature is at the operating temperature of the PWR evaporator, the alloys for this type of application must be properly handled. The test results in Figure 2-28 also show that Inconel 600 is more sensitive to intergranular corrosion than Incoloy 800 and 18-8 austenitic stainless steels. The reason is that the solid solubility of carbon in nickel-based alloys is low. As a result, tests have shown that at 650°C, the solid solubility of carbon in the alloy is only 0.01%. Supersaturated carbon in the alloy easily forms Cr23c6 and Cr7C3 along the grain boundary precipitation band along the grain boundary at the sensitizing temperature. The formation of chromium-depleted zones in the late 20th century confirmed the presence of chromium-depleted zones in the sensitized Inconel 600 alloy, as shown in Figure 2-29. From the figure, it can be seen that when sensitized at 700°C for 0.5 h, Cr7C3-dominant carbide precipitated along the grain boundaries, forming a chromium-depleted region of about 100 nm, and the chromium concentration in the depleted region decreased from 15% to 6%. After sensitization for 10h, the chromium concentration in the chromium depleted zone was less than 4%. Since then, with the extension of the sensitizing time, the chromium concentration in the depleted zone was gradually restored due to the back diffusion of chromium, and the chromium concentration in the chromium-depleted zone reached 100%. The 13% level has greatly improved the alloy’s resistance to intergranular corrosion. This resulted in an aging treatment process at a temperature of 1100°C and a suitable holding time at 700°C, ie a desensitization process (TTV). It has been successfully applied in the production process of Inconel 600 and Inco690 pressurizer evaporator heat transfer tubes. It provides protection against intergranular corrosion and intergranular stress corrosion of alloys.

Leave Your Message

Post time: May-31-2018