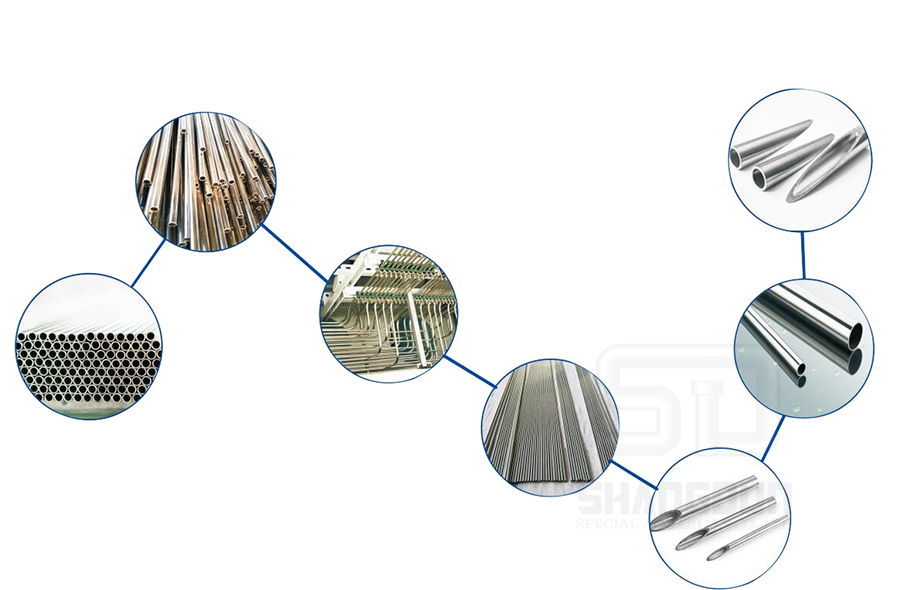

EP Tubes (electropolished tube) has stable chemical property, high pressure-proof ability, high strength widely used in special gas systems,medical devices,semi-conductor and liquid crystal industry.

一、Semiconductor Raw Material:

Ultra-Pure Stainless Steel AISI 316L

Principal Component Ratio(mass%)

| Smelting Method | (*ppm)Chemical composition of ultra-high purity materials | ||||||||||||

|

|

C |

Si |

S |

Mn |

P |

Cu |

Cr |

Ni |

Mo |

O* |

N* |

H* |

|

| SEMI F20 |

≤0.030 |

≤1.00 |

≤0.01 |

≤1.50 |

≤0.045 |

≤0.3 |

16.0~18.0 |

10.0~15.0 |

2.0~3.0 |

/ |

/ |

/ |

|

| (VIM+VAR) | SQ316L-Ⅰ |

0.005 |

0.2 |

0.001 |

0.6 |

0.003 |

0.010 |

17.7 |

14.80 |

2.70 |

8 |

30 |

1 |

| (VOD+VAR) | SQ316L-Ⅱ |

0.008 |

0.3 |

0.001 |

0.7 |

0.015 |

0.15 |

17.2 |

14.70 |

2.52 |

10 |

60 |

2 |

| (EAF+VOD+LF) | SQ316L-Ⅲ |

0.011 |

0.38 |

0.006 |

0.9 |

0.02 |

0.19 |

16.70 |

13.6 |

2.13 |

30 |

120 |

3 |

| (EAF+VOD) | SQ316L-Ⅳ |

0.021 |

0.42 |

0.007 |

0.9 |

0.02 |

0.25 |

16.15 |

10.08 |

2.13 |

40 |

150 |

5 |

Applications: Widely used in the manufacture of semiconductor products, ultra-high vacuum valve devices, filter housings and other stainless steels that require ultra-clean and ultra-low gas components.

( Key Technology: special smelting of VIM+VAR is used to reduce “non-metallic inclusion & gas composition ” in the production of materials .)

Nonmetallic Inclusions:

|

Grade |

ASTM-D Method(Worst Thin) |

|||||

|

0.5 1.0 1.5 2.0 2.5 (级) |

||||||

|

SQ316L-Ⅰ |

|

|

|

|

|

|

|

SQ316L-Ⅱ |

|

|

|

|

|

|

|

SQ316L-Ⅲ |

|

|

|

|

|

|

|

SQ316L-Ⅳ |

|

|

|

|

|

|

二、 Bright Annealed Precision Tube

Designation: TP304L, TP316L etc

Standards: ASTM A269,ASTM A213,GB13296, JIS G3459

Size:

|

美标英制规格ASTM |

美标规格ASTM |

日表规格JIS |

|||||

|

外径(OD) |

壁厚(T)mm |

外径(OD)mm |

壁厚(T)mm |

外径(OD) |

壁厚/T mm |

外径OD(mm) |

壁厚(T)mm |

|

1/8” |

0.5 |

3.18 |

0.5 |

||||

|

1/4” |

0.89 |

6.35 |

0.89 |

8A |

1.24 |

13.8 |

1.24 |

|

3/8” |

0.89 |

9.53 |

0.89 |

10A |

1.24 |

17.3 |

1.24 |

|

1/2” |

0.89 |

12.7 |

0.89 |

15A |

1.65 |

21.7 |

1.65 |

|

1/2” |

1.24 |

12.7 |

1.24 |

20A |

1.65 |

27.2 |

1.65 |

|

1/2” |

1.65 |

12.7 |

1.65 |

25A |

1.65 |

34 |

1.65 |

|

5/8” |

1.65 |

15.88 |

1.65 |

32A |

1.65 |

42.7 |

1.65 |

|

3/4” |

1.65 |

19.05 |

1.65 |

40A |

1.65 |

48.6 |

1.65 |

|

1” |

1.65 |

25.4 |

1.65 |

50A |

1.65 |

60.5 |

1.65 |

|

1.5” |

1.65 |

38.1 |

1.65 |

(Remark : Special Products Can Be Customized) | |||

|

2” |

1.65 |

50.8 |

1.65 |

||||

|

2.5” |

1.65 |

63.5 |

1.65 |

||||

Technical Reference:

Ordinary BA Tube:

Raw materials are from WALSIN、YONGXING、Baosteel, TISCO

Inner surface roughness<Ra0.4um,

Package:loose package deburring at both side.

2、Clean BA Tube:

Raw materials are imported from overseas or domestic vacuum metling (VIM)

Inner surface roughness<Ra0.3um

Package: each pipe with plastic bag & cap, plan end

3、 Ultra-Pure BA Tube:

Raw materials are imported or domestic vacuum metling(VIM+VAR).

Inner surface roughness<Ra0.2um,clean wash.

Package :both end with caps and plastic bags after clearing & fulled with nitrogen gas in dust-fress room

三、Stainless Steel EP Tube

Designation: TP316L(S:0.005~0.012)

Standards: ASTM A269& SEMEI F20-0706E, JIS G3459& SEMI F20-0706E , SEMI F19-0304,ASME BPE-2012

Size :

|

美标规格ASTM |

日表规格JIS |

|||||||

|

外径(OD) |

壁厚(T) |

外径(OD)mm |

壁厚(T)mm |

外径(OD) |

壁厚(T) |

外径(OD)mm |

壁厚(T)mm |

|

|

1/8” |

0.5 |

3.18 |

0.5 |

|||||

|

1/4” |

0.89 |

6.35 |

0.89 |

8A |

1.24 |

13.8 |

1.24 |

|

|

3/8” |

0.89 |

9.53 |

0.89 |

10A |

1.24 |

17.3 |

1.24 |

|

|

1/2” |

0.89 |

12.7 |

0.89 |

15A |

1.65 |

21.7 |

1.65 |

|

|

1/2” |

1.24 |

12.7 |

1.24 |

20A |

1.65 |

27.2 |

1.65 |

|

|

1/2” |

1.65 |

12.7 |

1.65 |

25A |

1.65 |

34 |

1.65 |

|

|

5/8” |

1.65 |

15.88 |

1.65 |

32A |

1.65 |

42.7 |

1.65 |

|

|

3/4” |

1.65 |

19.05 |

1.65 |

40A |

1.65 |

48.6 |

1.65 |

|

|

1” |

1.65 |

25.4 |

1.65 |

50A |

1.65 |

60.5 |

1.65 |

|

|

1.5” |

1.65 |

38.1 |

1.65 |

(Remark : Special Products Can Be Customized) | ||||

|

2” |

1.65 |

50.8 |

1.65 |

|||||

|

2.5” |

1.65 |

63.5 |

1.65 |

|||||

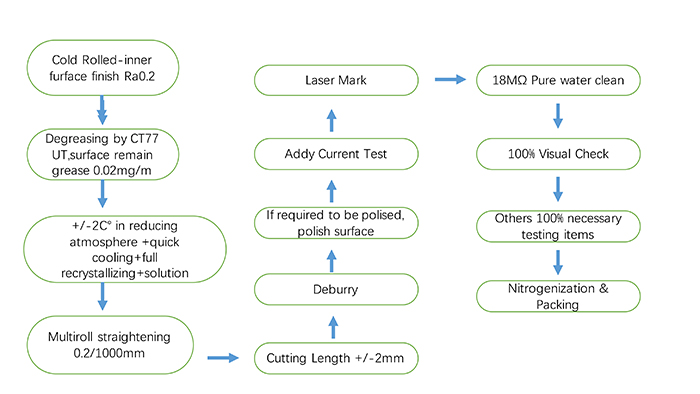

1、 Ordinary BPE GRADE EP Tube:

Raw Materials are from YONGXING, Baosteel,TISCO

Inner surface roughness<Ra0.25um,clean washing.

Package : both end with caps and two-layer plastic bag after clearing & fulled with nitrogen gas in dust-fress room. (General gas pipeline use.)

2、Clean HP GRADE EP Tube:

Raw materials are imported or domestic vacuum metling (VIM) from domestic mills.

Inner surface roughness<Ra0.2um.

Electrolytic layer Cr/Fe ≥1.5 after electrochemical polishing & clean wash.

The thickness of the oxide layer is greater than or equal to 1.5nm, the CPT critical pitting temperature is greater than 25°C, and the resistivity is greater than or equal to 18 megohms after ultrapure water cleaning.

Package: both end with caps and two-layer plastic bag and after full with nitrogen gas in dust-free room. (Special gas pipeline use.)

3、Ultra-Pure UHP GRADE EP Pipe:

Raw materials are imported or domestic vacuum metling(VIM+VAR)

Inner surface roughness<Ra0.125um

Electrolytic layer Cr/Fe ≥1.5 after electrochemical polishing & clean wash

The thickness of the oxide layer is greater than or equal to 1.5nm, the CPT critical pitting temperature is greater than 30°C, and the resistivity is greater than or equal to 18 megohms after ultrapure water cleaning.

Package :both end with caps and two-lays plastic bag after clearing & fulled with nitrogen in dust-free room. (Special high purity corrosive gas pipeline use.)

四、Corrosion Resistant Alloy BA Pipe:

Designation:Monel 400 (UNS N04400) ,UNS N02201 ; inconel 600(UNS N06600), N6 (UNS N02200),incoloy UNS N08800 , UNS N08810,UNSN06025,UNS N08825 ,Hastelloy UNS N10276, UNS N06022,UNS N08811, UNS N06059,UNS N10001,UNS N10665, UNS N06625, UNS N08028,UNS N06690, UNS N06601, UNS N06455 etc.

Standards: GB15011,JB4742,ASME SB-161, ASME SB-163, ASME SB-165, ASME SB-167, ASME SB – 622

Size: (OD):3.18~114.3mm , (WT):0.5~7.11mm, (L):≤8000mm

Materials are from Sinosteel, Baosteel, Tisco

Inner roughness : :Ra≦0.5um

Material designation:

|

Brand |

GB |

ASTM |

DIN |

BS |

AFNOR |

|

Incoloy 800 |

NS111 |

N08800 |

W.Nr.1.4876 |

NA15 |

Z8NC32.21 |

|

X10NiCrAlTi3220 |

|||||

|

Incoloy 800H |

NS112 |

NO8810 |

W.Nr.1.4958 |

NA 15 (H) |

|

|

X5 NiCrAlTi 31-20 |

|||||

|

Incoloy 800HT |

N08811 |

W.Nr.1.4959* |

|||

|

X 8 NiCrAlTi 32-21 |

|||||

|

Incoloy 825 |

NS142 |

N08825 |

W.Nr.2.4858 |

NA16 |

NC21FeDu |

|

NiCr21Mo |

|||||

|

Inconel 600 |

NS312 |

N06600 |

W.Nr.2.4816 |

NA14 |

NC15FE |

|

NiCrl 5Fe |

|||||

|

Inconel 601 |

NS313 |

N06601 |

W.Nr.2.4851 |

NC23FeA |

|

|

NiCr23Fe |

|||||

|

Inconel 625 |

NS336 |

N06625 |

W.Nr.2.4856 |

NA21 |

NC22DNb |

|

NiCr22Mo9Nb |

|||||

|

Inconel 718 |

GH4169 |

N07718 |

W.Nr.2.4668 |

NA 51 |

NC19FeNb |

|

NiCr19Fe19Nb5Mo3 |

|||||

|

Incoloy 926 |

N08926 |

W.Nr.1.4529 |

X1NiCrMoCu |

X1NiCrMoCu |

|

|

X1NiCrMoCu |

|||||

|

Inconel X-750 |

GH4145 |

N07750 |

W.Nr.2.4669 |

NC15TNbA |

|

|

NiCr15Fe7TiAl |

|

Brand |

GB |

ASTM |

DIN |

BS |

AFNOR |

|

Monel 400 |

N04400 |

W.Nr.2.4360 |

NA 12 |

Nu 30 |

|

|

NiCu30Fe |

|||||

|

Hastelloy B |

Ns321 |

N10001 |

|||

|

Hastelloy B-2 |

NS322 |

N10665 |

W.Nr.2.4617 |

NiMo28 |

|

|

NiMo28 |

|||||

|

Hastelloy C |

NS333 |

||||

|

Hastelloy C-22 |

N06022 |

W.Nr.2.4602 |

|||

|

Hastelloy C276 |

NS334 |

N10276 |

W.Nr.2.4819 |

NC17D |

|

|

NiMo16Cr15W |

|||||

|

254SMO |

S31254 |

W.Nr.1.4547 |

|||

|

904L |

N08904 |

W.Nr.1.4539 |

|||

|

GH1140 |

GH1140 |

||||

|

GH2132 |

GH2132 |

S66286 |

W.Nr.1.4890 |

||

|

Carpenter 20 |

NS143 |

N08020 |

W.Nr.2.4660 |

||

|

NiCr20CuMo |

五、Hastelloy EP TUBE

5.1、Raw Materials for purity Hastelloy series :

Principal Component Ratio(mass%)

|

Material |

Ni |

Mo |

Fe |

Mn |

C |

Si |

S |

Cr |

Ti |

P |

V |

Co |

W |

|

UNS N10276 |

Rest |

15.0-17.0 |

4.0-7.0 |

≤1.0 |

≤0.010 |

≤0.08 |

≤0.03 |

14.5-16.5 |

– |

≤0.040 |

≤0.35 |

≤2.5 |

3.0-4.5 |

|

UNS N06022 |

Rest |

12.5-14.5 |

2.0-6.0 |

≤0.5 |

≤0.015 |

≤0.08 |

≤0.02 |

20.0-22.5 |

– |

≤0.020 |

≤0.35 |

≤2.5 |

2.5-3.5 |

|

UNS N06455 |

Rest |

14.0-17.0 |

≤3.0 |

≤1.0 |

≤0.015 |

≤0.08 |

≤0.03 |

14.0-18.0 |

≤0.70 |

≤0.040 |

/ |

≤2.0 |

/ |

Application: Widely used in the manufacture of semiconductor products, ultra-high vacuum valve devices, filter housings, nuclear power, military and other super-corrosion, super-critical environments that require ultra-cleanliness and super corrosion resistance.

( Key Technology: special smelting of VIM+VAR is used to reduce “non-metallic inclusion & gas composition ” in the production of materials .)

Nonmetallic Inclusions:

|

GRADE |

ASTM-D METHOD(Worst Thin) |

|||||

|

0.5 1.0 1.5 2.0 2.5 |

||||||

|

S22(UNS N06022) |

|

|

|

|

|

|

|

S276(UNS N10276) |

|

|

|

|

|

|

5.2、Hastelloy EP Tube

Standards: ASME SB - 622& SEMEI F20-0706E, SEMI F19-0304,ASME BPE-2012

Size :

|

|

美标规格ASTM |

|

日表规格JIS |

|||||

|

外径(OD) |

壁厚(T) |

外径(OD) |

壁厚(T) |

|

外径(OD) |

壁厚(T) |

外径(OD) |

壁厚(T) |

|

1/4” |

0.89 |

6.35 |

0.89 |

|

8A |

1.24 |

13.8 |

1.24 |

|

3/8” |

0.89 |

9.53 |

0.89 |

|

10A |

1.24 |

17.3 |

1.24 |

|

1/2” |

0.89 |

12.7 |

0.89 |

|

15A |

1.65 |

21.7 |

1.65 |

|

1/2” |

1.24 |

12.7 |

1.24 |

|

20A |

1.65 |

27.2 |

1.65 |

|

1/2” |

1.65 |

12.7 |

1.65 |

|

25A |

1.65 |

34 |

1.65 |

|

5/8” |

1.65 |

15.88 |

1.65 |

|

32A |

1.65 |

42.7 |

1.65 |

|

3/4” |

1.65 |

19.05 |

1.65 |

|

40A |

1.65 |

48.6 |

1.65 |

|

1” |

1.65 |

25.4 |

1.65 |

|

50A |

1.65 |

60.5 |

1.65 |

|

1.5” |

1.65 |

38.1 |

1.65 |

|

(Remark : Special Products Can Be Customized) |

|||

|

2” |

1.65 |

50.8 |

1.65 |

|

||||

2、Ordinary BPE GRADE EP Tube:

Raw Materials are imported and domestic Baosteel, TISCO.

Inner surface roughness<Ra0.25um,clean washing.

Package: both end with caps and two-layer plastic bags after clearing & full with nitrogen gas in dust-fress room. (General gas pipeline use.)

3、 Clean HP GRADE EP Tube:

Raw material are imported or domestic vacuum metling (VIM)

Inner surface roughness<Ra0.2um.

Electrolytic layer Cr/Fe ≥1.5 after electrochemical polishing & clean wash.

The thickness of the oxide layer is greater than or equal to 1.5nm, the CPT critical pitting temperature is greater than 35°C, and the resistivity is greater than or equal to 18 megohms after ultrapure water cleaning

Package:both end with caps and two-layer plastic bags after clearing & full with nitrogen gas in dust-fress room. (Special gas pipeline use.)

六、 EP FITTINGS

We can do any custom angles ( From 7° to 180°.)

( Factory Standards ): EN 10253-2 / 10253 – 4 Typ A and B, DIN 2605 Part 1 and 2, ASME B16.9, production according to customer specification.

( Type of Elbow ):(long radius ) – 2D, 3D, 5D , (short radius ) – 2D, 3D, 5D, ( long radius & short radius – see center to center distance for further options )

(Materials):TP304L, TP316L, Inconel,Incoloy,Hastelloy

SIZE:1/4″~ 6″, roughness:Ra≦0.2um

BA tubes-bright annealing tubes: Manufacture process is double melt + cold rolled + bright annealing + clean processing

EP tubes-electrolytic polishing tubes:Electric polish BA tubes.