SHANGDUN SPECIAL MATERIALS CO.,LTD has the advanced Technology for EP bars,tubes and fittings in China .The company’s products are widely used in semiconductor, aerospace, nuclear power, ship, petrochemical and other fields, obtained the domestic and foreign customer’s high praise. We have a professional, preciseness, integrity, and responsible team.

Key Technology: special smelting of VIM+VAR is used to reduce “non-metallic inclusion & gas composition ” in the production of materials.

But for some environments only need VAR that can satisfy the needs. So we also could do 316L SS VAR EP which is complying with SEMI F20 standard. 316L is commonly used for high purity (HP) and ultra high purity (UHP) products, which has excellent corrosion resistance and oxidation resistance. 316L VAR reduces non-metallic inclusions by special refining to enhance the purity of the materials. Customers can choose different materials according to their actual needs.

Relevant standards for electropolishing and passivation treatment:

- ASTM E1558 Standard Guide for Electrolytic Polishing of Metallographic Specimens

- ASTM A380 Standard Practice for Cleaning, Descaling, and Passivation of Stainless Steel Parts, Equipment, and Systems

- ASTM A967 Standard Specification for Chemical Passivation Treatments for Stainless Steel Parts

Table 3

| Test Item | Test Standard |

| Surface roughness Ra | SEMI F37 |

| Oxide layer thickness | SEMI F72 |

| Surface defects | SEMI F73 |

| Cr/Fe | SEMI F60 |

| CrO/FeO | |

- Quality Inspection

Test methods include visual inspection, dimension inspection, surface roughness measurement, particle inspection, moisture testing, SEM, AES and ESCA or XPS.

- Cleaning and Packaging

SD EP tubing can effectively avoid contaminant residues with strict cleaning and packaging processes. EP tubing is ultrasonically cleaned, washed and rinsed, then purged and dried with ultra high purity hot nitrogen before being packaged in the NEBB-certified ISO 4 cleanroom.

SD EP tubing packaging complies with SEMI E49 standard. It is cleaned with ultra high pressure nitrogen, end capped, and bagged in double polyethylene bags with the inner bag filled with ultra high purity nitrogen to ensure the product’s cleanliness and maximize the protection of the product in the logistics and transportation process from damage.

- Prefabrication Services Available

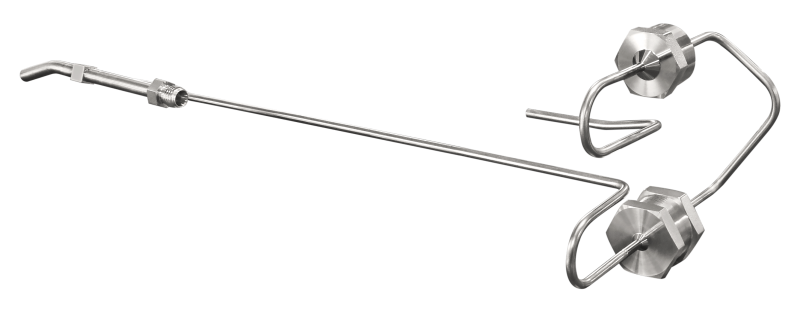

SD metals can provide EP bent tubing upon customer’s request. EP bent tubing integrate with SD metals high purity products (such as all-welded check valves, face seal fittings, welded fittings, diaphragm valves, regulators, etc.) to form EP bent tubing assemblies. SD can prefabricate EP bent tubing assemblies according to customers’ requirements to help customers improve installation efficiency.

Leave Your Message

Post time: Nov-22-2024