Austenitic stainless steel

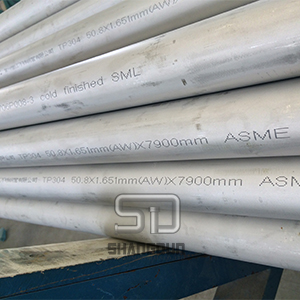

ASTM A312/ A312M,ASME SA312/SA312M Specification for seamless and welded austenitic stainless steel pipes

ASTM A450/A450M-02 Standard Specification for General Requirements for Carbon, Ferritic Alloy, and Austenitic Alloy Steel Tubes

ASTM A213/A213M,ASME SA213/SA213M Specification for seamless ferritic and austenitic alloy-steel boiler,superheater and heat-exchanger tubes

ASTM A269 Specification for seamless and welded austenitic stainless steel tubing for general service

ASTM A1016/A1016M Standard Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel Tubes

ASTM A358/A358M,ASME SA-358/SA-358M Specification for electric-fusion-welded austenitic chromium-nickel alloy steel pipe for high-temperature service

ASTM A249/A249M, ASME SA213/SA213M Specification for welded austenitic steel boiler,superheater,heat-exchanger, and condenser tubes

ASTM A268/A268M, ASME SA268/SA268M Seamless and welded ferritic and martensitic stainless steel tubing for general service

ASTM A511/A511M Specification for seamless stainless steel mechanical tubing

GOST 5632-72 High-alloy steels and corrosion-proof,heat-resisting and high-temperature alloys

EN10216-5 Seamless steel tubes for pressure purposes-Technical delivery conditions-Part 5: stainless steel tubes

DIN17458 Seamless circular austenitic stainless steel tubes subject to special requirements

ASTM A182/A182M Standard Specification for Forged or Rolled Alloy-Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service

ASTM A403/A403M Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings

| Standard | C | Si | Mn | P | S | N | Cr | Mo | Ni | Ti | Rp0.2 | Rm | El% (l) | Remark |

| ASTM A312 | max | max | max | |||||||||||

| Grade | Chemical Composition | Mechanical Porperty | Rearmk | |||||||||||

| TP316 | 0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16.00-18.00 | 2.00-3.00 | 11.00-14.00 | 205 | 515 | 35 | |||

| TP316L | 0.035 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16.00-18.00 | 2.00-3.00 | 10.00-14.00 | 170 | 485 | 35 | |||

| TP316Ti | 0.08 | ≤0.75 | ≤2.00 | 0.045 | 0.03 | ≤0.10 | 16.00~ 18.00 | 2.00~ 3.00 | 10.00~ 14.00 | 5(C+N) ~0.70 | 205 | 515 | 35 | |

| TP321 | 0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | ≤0.10 | 17.00-19.00 | 9.00-12.00 | 5(C+N) ~0.70 | 205 | 515 | 35 | OD≤9.5 | |

| 170 | 485 | 35 | OD≥9.5 | |||||||||||

| TP321H | 0.04-0.10 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | ≤0.10 | 17.00-19.00 | 9.00-12.00 | 4(C+N) ~0.60 | 205 | 515 | 35 | OD≤9.5 | |

| 170 | 480 | 35 | OD≥9.5 | |||||||||||

| TP304 | 0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18.00-20.00 | 8.00-11.00 | 205 | 515 | 35 | ||||

| TP304L | 0.035 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18.00-20.00 | 8.00-13.00 | 170 | 485 | 35 | ||||

| TP304H | 0.04-0.10 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18.00-20.00 | 8.00-11.00 | 205 | 515 | 35 | ||||

|

|

|

| Standard | C | Si | Mn | P | S | N | Cr | Mo | Ni | Ti | Rp0.2 | Rm | El% (l) | Remark |

| ASTM A213 | max | max | max | |||||||||||

| Grade | Chemical Composition | Mechanical Porperty | Hardness | |||||||||||

| TP316 | 0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16.00-18.00 | 2.00-3.00 | 10.00-14.00 | 205 | 515 | 35 | ≤90 | ||

| TP316L | 0.035 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16.00-18.00 | 2.00-3.00 | 10.00-14.00 | 170 | 485 | 35 | ≤90 | ||

| TP316Ti | 0.08 | ≤0.75 | ≤2.00 | 0.045 | 0.03 | ≤0.10 | 16.00-18.00 | 2.00-3.00 | 10.00-14.00 | 5*(C+N)-0.70 | 205 | 515 | 35 | ≤90 |

| TP321 | 0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 17.00-19.00 | 9.00-12.00 | 5*(C+N)-0.70 | 205 | 515 | 35 | ≤90 | ||

| TP321H | 0.04-0.10 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 17.00-19.00 | 9.00-12.00 | 4*(C+N)-0.70 | 205 | 515 | 35 | ≤90 | ||

| TP304 | 0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18.00-20.00 | 8.00-11.00 | 205 | 515 | 35 | ≤90 | |||

| TP304L | 0.035 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18.00-20.00 | 8.00-12.00 | 170 | 485 | 35 | ≤90 | |||

|

|

|

| Standard | C | Si | Mn | P | S | N | Cr | Mo | Ni | Ti | Rp0.2 | Rp1.0 | Rm | El% (l) |

| EN 10216-5 | max | max | max | |||||||||||

| Grade | Chemical Composition | Mechanical Porperty | ||||||||||||

| 1.4401 | 0.07 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 16.5-18.5 | 2.00-2.50 | 10.00-13.00 | 205 | 240 | 510-710 | 40 | |

| 1.4404 | 0.03 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 16.50-18.50 | 2.00-2.50 | 10.00-13.00 | 190 | 225 | 490-690 | 40 | |

| 1.4571 | 0.08 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | 16.5-18.5 | 2.00-2.50 | 10.50-13.50 | 5*C-0.70 | 210 | 245 | 500-730 | 35 | |

| 1.4541 | 0.08 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | 17.00-19.00 | 9.00-12.00 | 5*C-0.70 | 200 | 235 | 500-730 | 35 | ||

| 1.4301 | 0.07 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 17.0-19.5 | 8.00-10.50 | 195 | 230 | 500-700 | 40 | ||

| 1.4307 | 0.03 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 17.50-19.50 | 8.00-10.00 | 180 | 215 | 460-680 | 40 | ||

| 1.4306 | 0.03 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 18.0-20.00 | 10.00-12.00 | 180 | 215 | 460-680 | 40 | ||

|

|

| Standard | C | Si | Mn | P | S | N | Cr | Mo | Ni | Ti | Rp0.2 | Rp1.0 | Rm | El% (l) | Remark |

| EN 10216-5/A312 | max | max | max | ||||||||||||

| Grade | Chemical Composition | Mechanical Porperty | |||||||||||||

| TP316/TP316L | 0.035 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16.00-18.00 | 2.00-3.00 | 11.00-14.00 | 205 | - | 515 | 35 | |||

| 1.4404/1.4401 | 0.03 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 16.50-18.50 | 2.00-2.50 | 10.00-13.00 | 205 | 240 | 510-690 | 40 | ||

| 1.4404/TP316L | 0.03 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 16.50-18.00 | 2.00-2.50 | 10.00-13.00 | 190 | 225 | 490-690 | 40 | ||

| 1.4404/1.4401/TP316L/TP316 | 0.03 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 16.50-18.00 | 2.00-2.50 | 11.00 -13.00 | 205 | 240 | 515-690 | 40 | ||

| 1.4571/TP316Ti | 0.08 | ≤0.75 | ≤2.00 | 0.04 | 0.015 | ≤0.10 | 16.50 -18.00 | 2.00- 2.50 | 10.50-13.50 | 5*(C+N )to 0.70 | 210 | 245 | 515-730 | 35 | |

| 1.4541/TP321 | 0.08 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.10 | 17.00-19.00 | 9.00-12.00 | 5*(C+N) to 0.70 | 205 | 235 | 515-730 | 35 | OD≤9.5 | |

| 200 | 235 | 500-730 | 35 | OD≥9.5 | |||||||||||

| 1.4541/TP321/TP321H | 0.04-0.08 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.10 | 17.00 -19.00 | 9.00-12.00 | 5*(C+N) to 0.60 | 205 | 235 | 515-730 | 35 | OD≤9.5 | |

| 200 | 235 | 500-730 | 35 | OD≥9.5 | |||||||||||

| TP304/TP304L | 0.035 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18.00-20.00 | 8.00-11.00 | 205 | - | 515 | 35 | ||||

| 1.4301/TP304 | 0.07 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 18.00-19.50 | 8.00-10.50 | 205 | 230 | 515-700 | 40 | |||

| 1.4301/1.4307 | 0.03 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 17.50-19.50 | 8.00 -10.00 | 195 | 230 | 500-680 | 40 | |||

| 1.4301/ TP304/TP304L | 0.035 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 18.00-19.50 | 8.00-10.50 | 205 | 230 | 515-700 | 40 | |||

| 1.4301/1.4307/TP304/TP304L | 0.03 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 18.00-19.50 | 8.00-10.00 | 205 | 230 | 515-680 | 40 | |||

|

|

| Standard | C | Si | Mn | P | S | N | Cr | Mo | Ni | Ti | Rp0.2 | Rp1.0 | Rm | El% (l) | Remark |

| EN 10216-5/SEW 470/ASTM A213 | max | max | max | ||||||||||||

| Grade | Chemical Composition | Mechanical Porperty | Hardness | ||||||||||||

| 1.4404/1.4401 | 0.03 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 16.50-18.50 | 2.00-2.50 | 10.00-13.00 | 205 | 240 | 510-690 | 40 | ≤90 | |

| 1.4404/1.4401/TP316/TP316L | 0.03 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 16.50-18.00 | 2.00-2.50 | 10.00-13.00 | 205 | 240 | 515-690 | 40 | ≤90 | |

| 1.4571/TP316Ti | 0.08 | ≤0.75 | ≤2.00 | 0.04 | 0.015 | ≤0.10 | 16.50-18.00 | 2.00-2.50 | 10.50-13.50 | 5*(C+N)-0.70 | 210 | 245 | 515-730 | 35 | ≤90 |

| TP321/TP321H | 0.04-0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 17.00-19.00 | 9.00-12.00 | 5*(C+N)-0.70 | 205 | - | 515 | 35 | ≤90 | ||

| 1.4541/1.4878 | 0.08 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | 17.00-19.00 | 9.00-12.00 | 5*C-0.70 | 210 | 235 | 500-730 | 40 | - | ||

| 1.4541/1.4878/TP321/TP321H | 0.04-0.08 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | 17.00-19.00 | 9.00-12.00 | 5*(C+N)-0.70 | 210 | 235 | 515-730 | 40 | ≤90 | ||

| 1.4878 | 0.12 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 17.00-19.00 | 9.00-12.00 | 4*C-0.80 | 210 | - | 500-750 | 40 | - | ||

| TP304/TP304L | 0.035 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18.00-20.00 | 8.00-11.00 | 205 | - | 515 | 35 | ≤90 | |||

| 1.4301/1.4307 | 0.03 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 17.50-19.50 | 8.00 -10.00 | 195 | 230 | 500-680 | 40 | ≤90 | ||

| 1.4301/1.4307/TP304/TP304L | 0.03 | ≤1.00 | ≤2.00 | 0.04 | 0.015 | ≤0.11 | 18.00-19.50 | 8.00-10.00 | 205 | 230 | 515-680 | 40 | ≤90 | ||

|

|

|

|